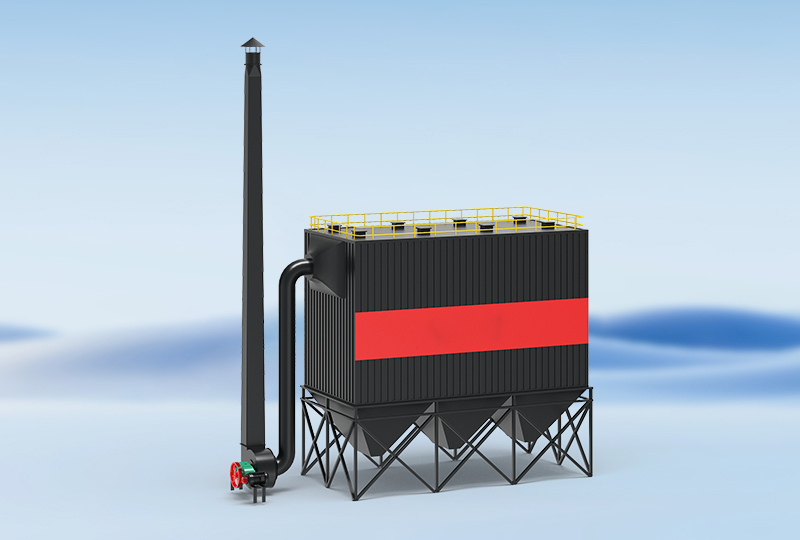

PPCS Series Air Box Pulse Dust Collector

INTRODUCTION

PPCS series air box pulse bag dust collector is widely used in building materials, cement, metallurgy, machinery, chemical and refractory industries, especially for cement plant crushing, packaging, warehouse roof, clinker cooling machine and all kinds of mills and other dust collection system (or dust removal system), strong applicability.

WORKING PRINCIPLE

Dusty gas goes in from the air intake of the dust collector and into the ash bucket through the partition board, and at the same time the air flow slows down. Due to the inertia, the coarse particles in the gas will fall into the ash bucket, and the fine dust particles will go up along with the gas and into the filtering chamber. The powder dust will stick onto the surface of the filter bag, and the purified gas will go into the upper cleaning room through the filter bag and be sucked by the main air blower of the dust collecting system and discharged into the air.

ADVANTAGES

– Off-line cleaning

– Wide application range

– Large processing air volume

– High dust collection efficiency

Technical Specifications

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.